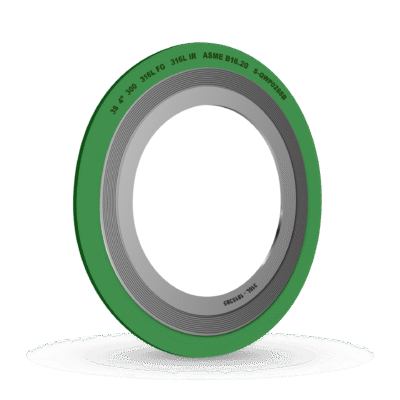

Description

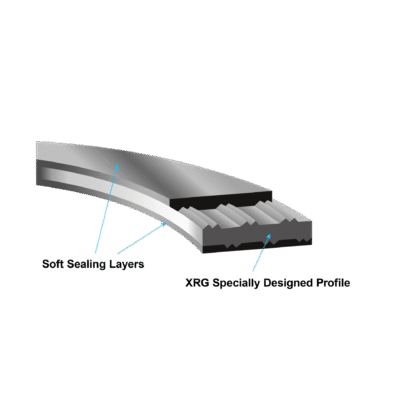

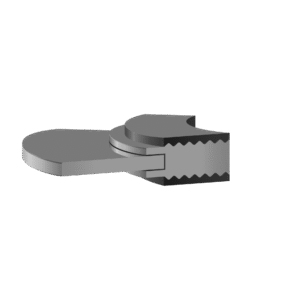

3S – Kammprofile gaskets are manufactured with the best practices utilizing the latest manufacturing technology. This style is the preferred gasket choice to maintain a tight seal for heat exchangers, pressure vessels, and other equipment that are subjected to excessive thermal cycling. Kammprofile gaskets are constructed with concentrically serrated solid metal core faced on both sides with a flexible sealing material. These are commonly specified to improve performance where lower gasket seating stresses are required

for an effective seal. This design limits the movement of the sealing material within the serrations while the solid metal core provides blowout resistance and firmness for ease of installation.

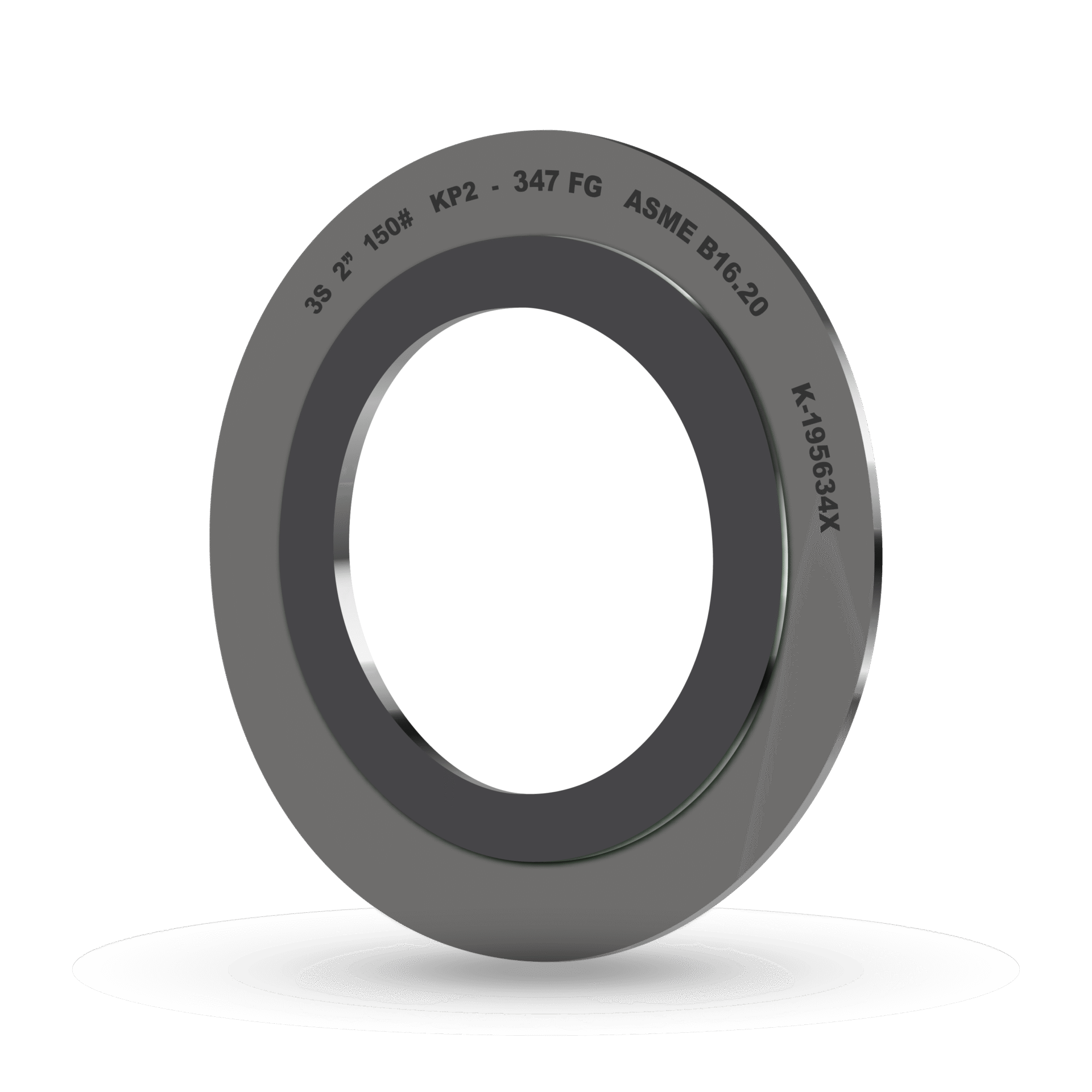

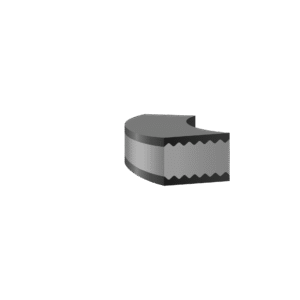

Style:

KP-1 is constructed with solid serrated core only for use in confined spaces, male and female, tongue and groove, or recessed flange compositions. These are most commonly found in heat exchanger flanges as upgrade from double jacketed or solid metal where lower bolt load is required

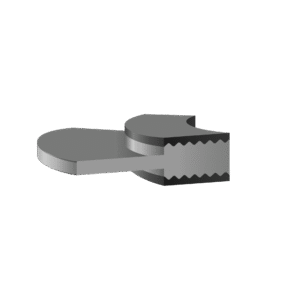

KP-2 is fabricated similar to KP-1, except with an integral outer guide ring to assist in proper alignment on flange facing. This gasket is recommended for raised face or flat face mating flanges

KP-3 is very similar to our KP-2 with minor difference of utilizing a loose-fitting guide ring for alignment. This design is used in place of KP-2 where thermal expansion is encountered

FIRE SAFE APPROVED ACCORDING TO API 6FB (GRAPHITE FACING)